Shielding

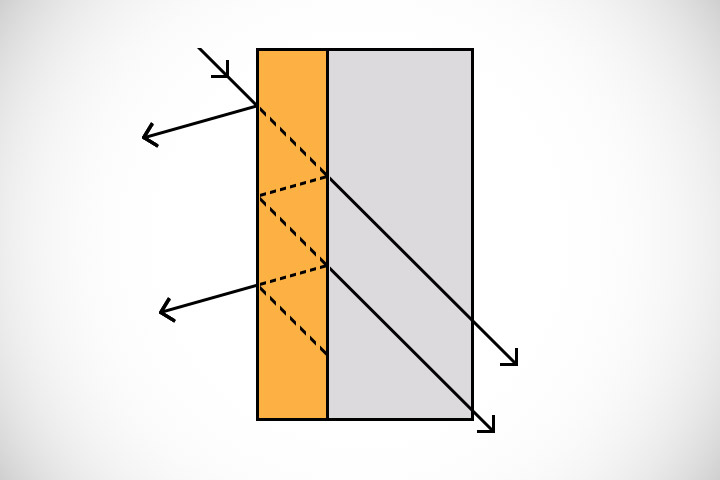

The most popular and cost effective method of achieving EMC involves the use of electrically conductive, resin bonded shielding coatings. Conductive fillers (graphite, silver, nickel, copper) dispersed in a resin matrix are applied on the plastic enclosure with conventional spray equipment. NICKEL COATING is now the European industry standard for shielding plastic enclosures of electronic and telecommunications equipment. COPPER COATING is used as shielding coating with better reflective properties at lower frequencies than nickel. SILVER COATING is the highest guarantee against the electromagnetic emissions.TEKO service center support the customers in case of technical requirements.

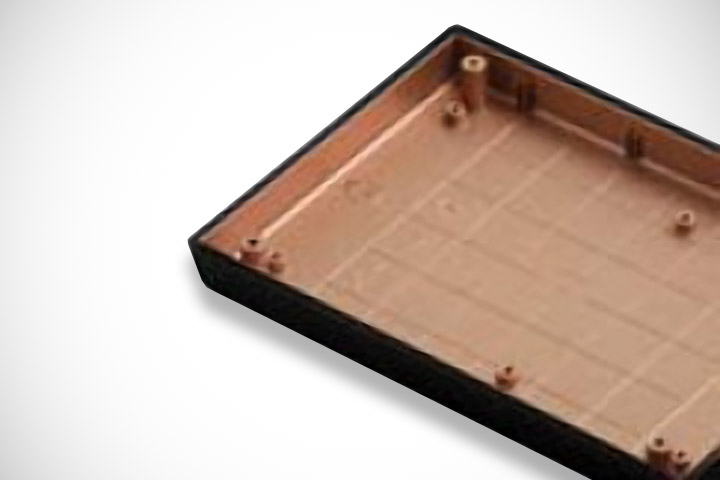

TEKO has developed ways of shielding the enclosures from either incoming or outgoing radiations or signals. TEKO offers a resin bonded shielding coatings based on conductive pigments such as copper, nickel,silver or copper/silver. The plastic enclosures are sprayed with the conductive lacquer on the interior surfaces.